Reviving the Steel Industry with Green Innovation

The steel industry plays a critical role in the global economy, yet it is also one of the largest contributors to greenhouse gas emissions. As countries rush to meet ambitious carbon reduction goals, companies focused on producing "green" steel are stepping up to the plate, advocating for low-carbon production methods. Understanding this shift is vital not just for environmental advocates but for anyone invested in the future of industry and infrastructure.

At the heart of this transformation is the innovative process employed by companies like Boston Metal and Electra. Traditional steel production relies heavily on fossil fuels and blast furnaces, contributing significantly to global emissions—11% to be exact, a figure equivalent to all private vehicle emissions combined. Boston Metal, for instance, has developed a groundbreaking method using electricity to separate impurities from iron ore. By heating an electrolyte solution to an extreme 1600 °C, they extract liquid iron through electrolysis, significantly reducing carbon footprint. This electric arc technology already shows promise in making American steel production cleaner by utilizing less carbon-intensive methods, as electric arc furnaces are already more common and eco-friendlier than conventional techniques.

The compelling part about these innovations lies in their scalability. Electra’s approach, which operates at much lower temperatures (60-100 °C), employs an acidic electrolyte to deposit iron onto plates, a method akin to how copper and zinc are produced. While the initial costs for this production might be higher, as demand increases and technology improves, this “green premium” could disappear. Projects are cropping up, like Electra's demonstration plant, which aims to produce 500 tons of iron annually, highlighting real-world applications of these concepts. Moreover, these companies indicate a broader societal shift towards recognizing the value of sustainability in industry, prompting questions about how far we can realistically transition before reaching a tipping point for costs versus environmental impact.

In conclusion, while the journey of transitioning to green steel production is fraught with challenges, it also holds immense potential for mitigating climate change across industries. The path to cleaner steel is not just about environmental responsibility; it's about reimagining the future of industrial production itself. Those interested in exploring further can look into resources on electrolysis technology and ongoing research on sustainable manufacturing practices.

Read These Next

Global Leaders and Tech CEOs Unite in Paris for AI Summit

A summit in Paris addressed AI innovation and responsibility, emphasizing the need for international cooperation and regulation.

China Calls on US to Avoid Politics in COVID-19 Origins Probe

China urges the US to halt political maneuvering on COVID-19 origins, emphasizing transparency and international collaboration.

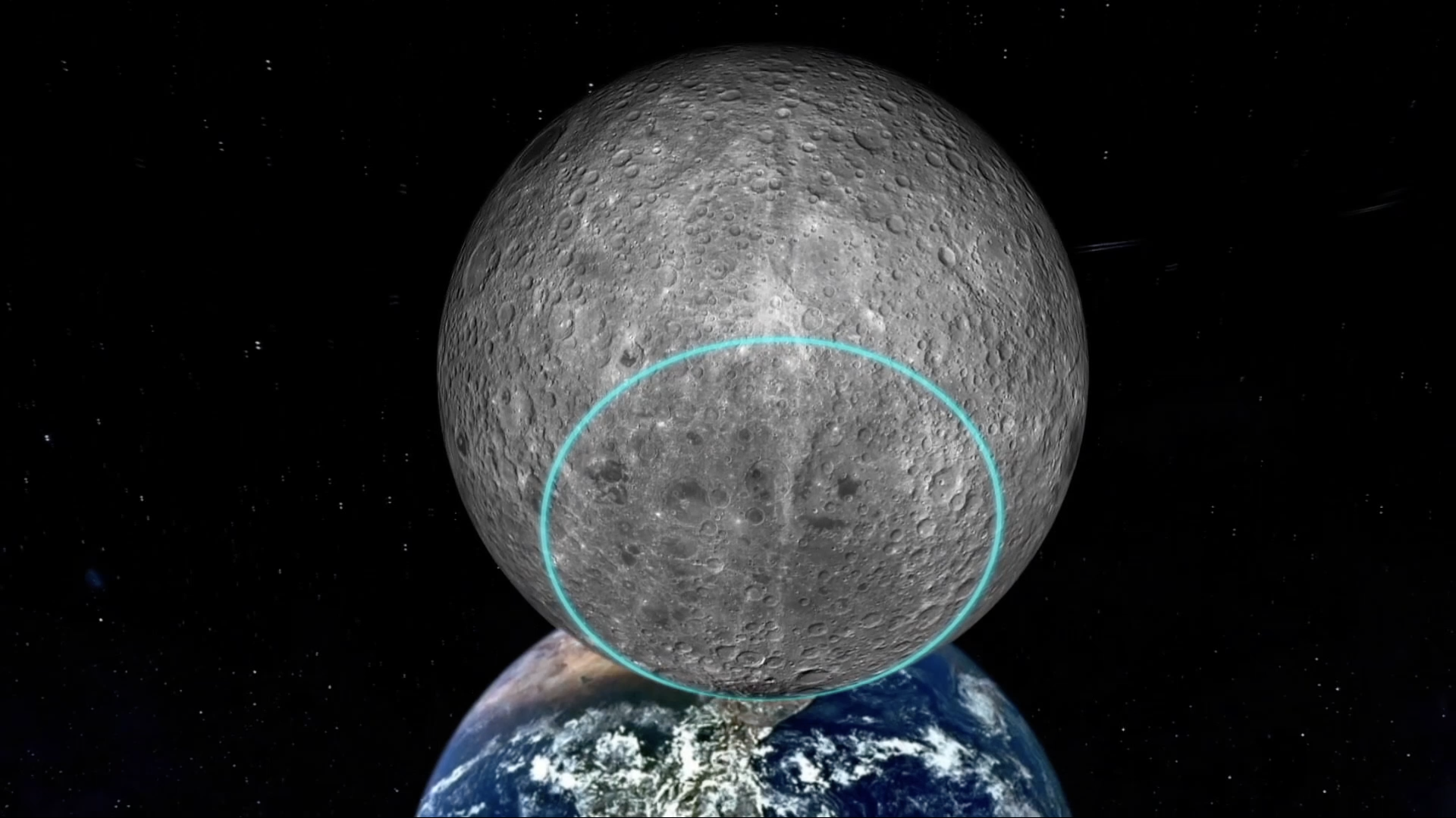

Moon Soil Samples to be Featured at World Expo 2023

Moon soil samples from China’s Chang'e-6 mission will be showcased together for the first time at World Expo 2025 in Osaka.